Of course this cold process permits to save energy and to obtain homogeneous particle mixtures linked together at microscopic level keeping good technological properties. The only solvent that is used, at low percentages, is water and so this procedure can be defined as a clean and environmental friendly technology.

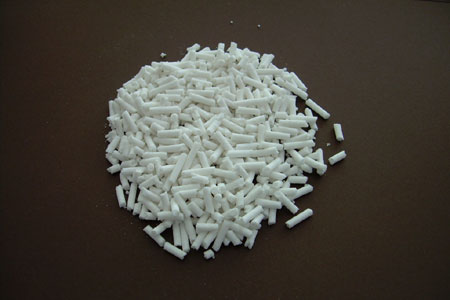

This new technology produces pellets that can be subsequently processed by using traditional plastic equipments such as extrusion, injection molding and so on.

In order to produce these pellets a special new machinery was designed to get by Cold Plasting homogeneous compressed/extruded product.

Different blends, compounds and composites have already prepared and characterized by using Cold Plast technology.

In the following table some data referred to a Polycarbonate/ABS/SAN blend are shown. In particular pellets of this material were produced by mixing powders of PC, ABS and SAN and 3 % of cellulosic binder by using an appropriate pelleting equipment. Subsequently PC/ABS/SAN/FV blend samples were prepared by using injection moulding machine and characterized.

| (65pe% PC + 25% ABS + 10% SAN) BLEND | ||||

|---|---|---|---|---|

| Properties | ISO Standard | Measure Unit | Typical Values | |

| M.F.I. 260°C/5 Kg | 1133 | g/10´ | 19.4 | |

| IZOD Resilience c.i. 4 mm | 180/1A | KJ/m² | 37 | |

| CHARPY Resilience s.i. 4 mm | 179/1eU | KJ/m² | NB | |

| VICAT B/ 50°C | 306 | °C | 110 | |

| Flexural Max load | 178 | MPa | 67 | |

| Elastic Modulus | 178 | MPa | 2000 | |

| H.D.T. 1.82 MPa | 75 | °C | 105 | |

| Tensile max load | 527 | MPa | At yield 41.6 | At break 36.3 |

| Tensile elongation | 527 | % | At yield 6.4 | At break 40 |

| Density | 1183 | g/cm³ | 01.10.00 | |

| Longitudinal shrinkage | internal | % | 1 | |

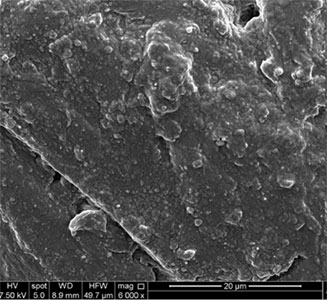

The morphological analysis was performed by using an FEI environmental scanning electron microscope (ESEM) on cryogenically fractured surfaces of the composite after injection moulding (See micrograph below). From the micrographs observation no phase separation are evident in the injected sample. In conclusion we can assess that the innovative preparation of these blends is able to achieve homogeneous materials characterized by very good final properties.